If you want to remain on the cutting edge of manufacturing excellence, then research and development must be a part of your business model. There are always ways to improve manufacturing processes. Some of these involve incremental improvements whereas others require more dramatic changes. The dramatic changes require research and development.

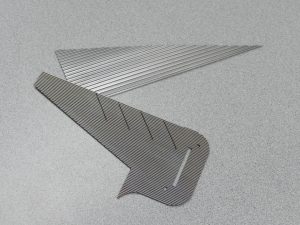

- Profiled Fin Development

- Fin Cleaning

- Fin Cleaning

Innovative Automation has a long history of R&D. When we started the company in 2000, we focused primarily on engineering as well as R&D projects. Taking a chance on something new is very much in our DNA as a technologically root firm. Our customers would turn to us after talking to more conventional automation companies in the industry about a new development project they were hoping bring to fruition. There they were often told that their project was impractical if not impossible. In many instances, we have taken these impossible projects and made them possible.

3D Tooling Development

We have modeled our organization based upon its strengths in engineering. We are also more than willing to “play the long game” knowing that R&D does not necessarily provide immediate payback but that over time it can be very much worthwhile.

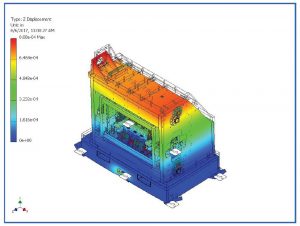

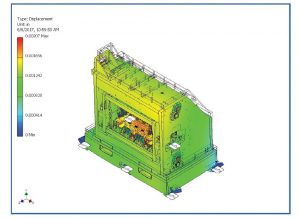

- Fin Press FEA

- Fin Press FEA

The key to our execution of R&D projects is to partner with our customers and to focus on the Stage/Gate principles of the IA Method. This Stage/Gate philosophy allows us to break large challenges into more reasonable smaller goals. Progress towards these goals are continuously evaluated. This method allows us to mitigate risk and reduce overall R&D investment while providing a structured path to the overall objective. A great example of this was a project in which we utilized 3D printed tools to model the product prior to committing to very expensive metal production tooling. We welcome the opportunity to partner with you on your R&D projects. These are the projects that make engineering enjoyable for all of us at IA.