Tube handling and processing are important functions for many manufacturing operations. A remarkable number of the products that we use every day utilize some form of tubing as part of their construction. The processing of these tubes can take on a variety of methods and styles.

- Tube Profiler Cut

- Tube Profiler

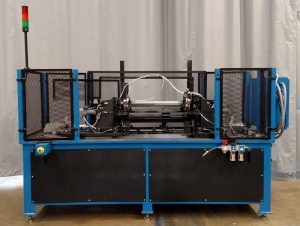

Tube Processing is a relatively generic term for operations that occur following the forming or rolling of the tube. These processes can be something specialized like swaging, or can be more standard operations like cutting, punching, trimming, or bending. More importantly, when properly engineered, these operations can be combined within a single system to allow for the final processing of the tube.

The utilization of the IA Method is critical to the configuration of a tube processing system. We work with our customer’s specific requirements to determine the optimum combination of processes and methods to achieve the end product with volumes and model mix that maximize the value provided to the customer.

In many cases, tube processing involves some manner of punching and trimming. In some cases, both methods are utilized. When this is the case, we have often tied the processes together through the utilization of a walking beam transfer or some other part handling method. This allows for the maximization of the throughput while making sure that the only manual intervention will be tending to the incoming and outgoing material. As is the case in all of our systems, we welcome the opportunity to engineer a system specifically for your application requirements.

Visit Tridan for even more Tube Production Machines.