As important as a Fin Mill is to the production of a quality fin, the Roll Forming Tool or Fin Tool might be even more important. This tooling is largely responsible for all of the quality aspects of the fin being produced including the height and the final fin density. Every functional fin manufacturing process starts with a quality fin as produced from the form roll. If the form roll is not performing its function properly, there is not much chance for the remainder of the fin mill to overcome this discrepancy.

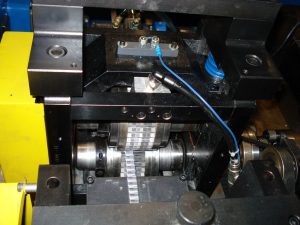

Rollform Tooling 1

A lot goes into the design and manufacture of a quality form roll. Understanding of the impact of the fin design, the material, and the manner in which it will be run, all have an influence over the design of the form tool. Manufacturing of the tool is also a challenge in precision manufacturing as the tolerances are very tight in order to allow the tool to function as designed.

- Rollform Tooling 2

- Rollform Tooling 3

IA’s advantage in the design and build of fin tooling is experience. With the Livernois brand of tooling, we have a history of tools for over 1000 different fin designs covering applications dating back over 60 years. This extensive library can be queried for heights, materials, and a number of other fin design parameters allowing us to accurately determine the proper design for any new fin. Combine this with in-house manufacturing methods that have been honed since the beginning of fin tool development and we can readily provide tooling to meet the demands of your fin application.

Rollform Tooling 4