There are a great number of manufactured components that are formed in some manner of continuous process. These can be roll formed, reciprocally stamped, extruded, or formed via some other method. Since most processes cannot use these components as continuous strips, they must be cut at some time in order to be utilized. Sometimes this process is in-line with the forming process and at other times it is an offline process. IA has experience with each of these types of processing methods.

- Die Blade Cutoff

- Wavy Cutoff Tool

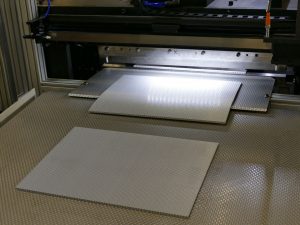

- Fin Mill Circular Cutoff

A number of parameters are involved in feeding and cutting applications in order to assure the delivery of a quality part. Feeding requires not only the processing of the part but also the feedback of the measurement method. In the case of roll formed fins, this could consist of the metering and measuring of the number of convolutions that are fed. For extrusions is may be a matter of the length of finished form that has been fed.

Once we have determined how best to feed the components and have developed a measurement method for the feed, we have to complete the cut. In the past we have produced cutoffs that are shear blades, saws, profiled shears, or even dies. We have designed systems to produce a single ended cut and also dual ended cuts. Whatever method works best for the application is the method that we will use to get the optimal solution for the application.